Procurement - the Secret Sauce of MRO

/warehouse.jpg)

Maintenance, Repair, and Operations (MRO) is big. America’s 350,000-plus mining and manufacturing facilities annually spend nearly $200 billion on indirect MRO materials. A large percentage of these facilities don’t actively manage the specification, purchase, storage, and consumption of indirect materials (items such as tools, bearings, motors, etc.) to the same extent that they manage their direct materials (steel, plastic, production chemicals, etc.).1

MRO is also essential. For any capital-intensive business – those with manufacturing facilities, extensive IT operations, real estate holdings, fleet operations, etc. – effective MRO is essential to business success. Without an effective MRO function, issues with Property, Plant, and Equipment can slow or even stop operations, frustrating employees, angering customers, and creating a drag on profits.

Is there a way to better manage MRO spending without negatively impacting uptime? The savings payoff is there for companies willing to seize the opportunity. James Hallock of CoreTrust, says, “experience has shown that a disciplined approach to [MRO] can return savings of 15-18%.”2

Companies have traditionally relied on Computerized Maintenance Management Systems (CMMS) or the broader Enterprise Asset Management (EAM) software to manage MRO. Maintenance departments use these systems to:

- Generate work orders

- Assign resources

- Create bills of material

- Schedule jobs

This functionality is required for successful MRO management but is only half of the story. Effective inventory management is the other half. After all, you can do all the above but without the proper inventory, no work can be done. Organizations must have the right parts in the right quantities at the right time.

According to analyst firm Aberdeen, MRO inventory optimization is the way to go. Best-in-Class companies understand the importance of having an inventory stocking strategy for spare parts to minimize costs. This means accurately assessing how many spare parts are kept on hand and what agreements are in place with suppliers to keep big ticket items in stock whose shipment happens on an expedited basis. To accurately forecast and plan inventory demands, a company must have real-time visibility into its inventory information.3

Best-in-Class maintenance organizations have real-time visibility into their fill-rates, stock out rates, inventory accuracy, and shelf turns. Another key element to this visibility is understanding who the suppliers are for spare parts, how much is spent with them, where and on which items. Without this information, maintenance departments are fighting in the dark against an invisible enemy. Working collaboratively with suppliers will enable manufacturers to determine how to minimize shipping and warehousing costs.3

While this may sound simple, inventory management is quite challenging. If organizations maintain too little inventory, they run the risk of system downtime. Too much inventory results in excessive working capital utilization and high depreciation expense. Complicating this picture is the unpredictable, complex nature of MRO.

Companies must deal with a variety of makes and models of equipment which require different parts. This equipment may be located at multiple sites. Unplanned repairs are common, driving unexpected demand for parts & supplies. These parts and supplies vary from low cost, commodity consumables (fasteners, lubricants, etc.) to high-end, expensive components (pumps, motors, etc.).

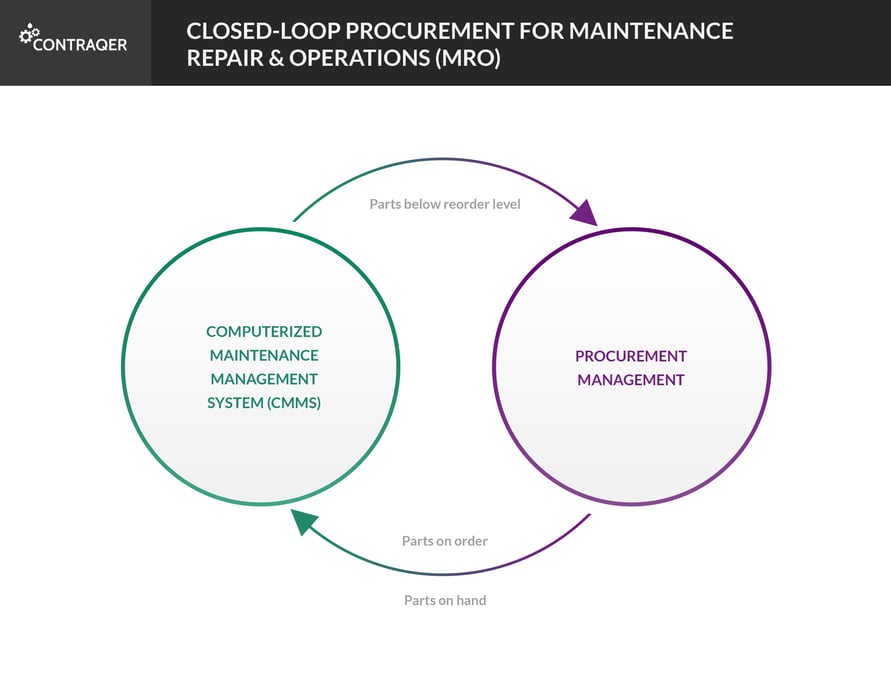

To address this complexity, companies need sophisticated procurement capability that provides seamless, real-time inventory data integration with their CMMS/EAM system to create Closed-Loop MRO Procurement.

Closed-Loop MRO Procurement

In Closed-Loop MRO Procurement, the procurement system monitors the CMMS/EAM in real time to determine when parts go below their re-order points. When this happens, the system creates an RFQ or Purchase Order and alerts the Procurement team that they need to make a purchase. When a Purchase Order is placed, the system automatically updates the Quantity on Order information in the CMMS/EAM. And when the order arrives, the system automatically decrements the Quantity on Order information and increments the Quantity on Hand information.

The benefits of Closed-Loop MRO Procurement include:

- Fewer parts outages which results in higher uptime and more reliable assets & equipment

- Fewer emergency shipments, resulting in lower shipping costs

- Lower inventory levels, resulting in both lower depreciation expense and lower working capital utilization

- Lower purchase prices, resulting in a lower overall maintenance spend

- Lots of time saved and more accurate inventory information through the elimination of tedious, manual work

What is the impact of Closed-Loop MRO Procurement on the bottom line? Through a combination of real-time asset data, predictive analytics, and continuous improvement, Best-in-Class companies see 12% less unscheduled asset downtime and 15% higher operating margins compared to Laggards.3

Clearly the automation of procurement in general and MRO procurement in particular can have a dramatic impact on the bottom line. The right procurement management system can be the secret sauce to enable Closed-Loop MRO.

Contact us to learn more about Closed-Loop MRO and what it can do for your profitability and efficiency.

- Spend Matters cited Paul V. Arnold, former Editor-in-Chief of Reliable Plant. “Indirect focus directly impacts plant”

- James Hallock, Procurement Leaders – Global Intelligent Network - “A Roadmap For MRO Savings And Efficiencies”

- Reid Paquin, Research Analyst, Aberdeen Group. “The Importance of Inventory Optimization and MRO”

JOIN OUR

MAILING LIST

RELATED POST

- Don’t force a square peg into a round hole

- Be a better buyer with Closed-Loop Maintenance, Repair, and Operations (MRO) Purchasing

- Contraqer Corp. Partners with Smartware Group to Enable Closed-Loop MRO Procurement

- Contraqer Successfully Deploys Closed-Loop MRO Procurement Solution at Grassland Dairy Products, Inc.